If required, we can perform RF analysis, create sample panels and coordinate RF testing, provide structural analysis, and build custom tooling for a radome size or shape variation. We can also provide architectural structures and dome designs for building contractors.

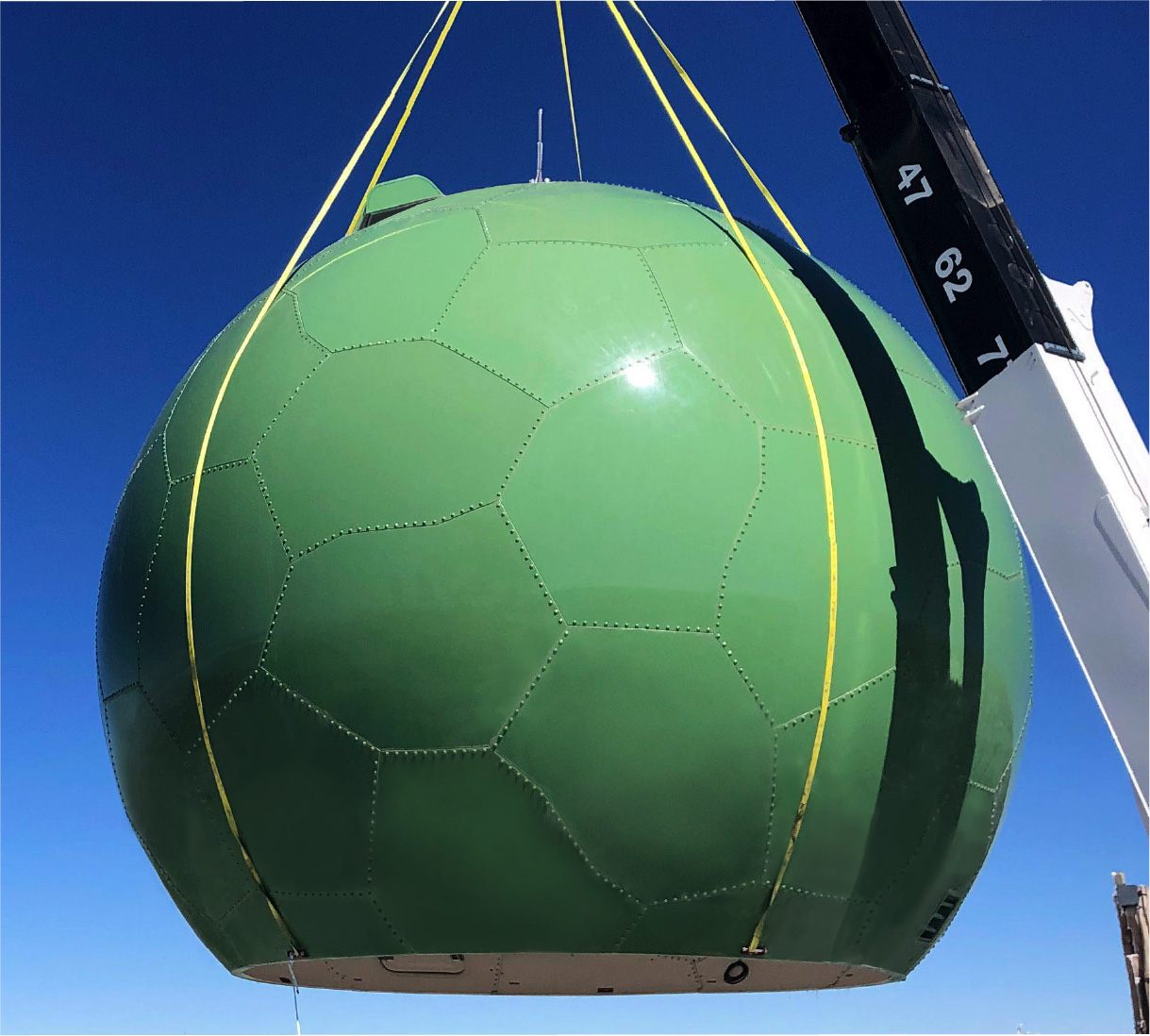

Our team can assist in radome installation from the initial site survey to construction support. Whether you require full installation or a project supervisor, we want to ensure your radome is installed as quickly and safely as possible.

The manufacturing facility in Reno, NV can provide large-scale milling services for companies and Universities when it is not busy with our radome products.

IT RCS radomes are provided with installation guides, operation manuals, maintenance manuals, and repair manuals that follow the best commercial practices. The installation guide can assist the end user in completing the radome installation with their own team if desired. A basic set of hand tools to maintain the radome and a repair kit for minor repairs are also supplied with each radome.

If you require installation support, we can provide radome installation services worldwide, utilizing qualified crews or project supervisors. Our crews have experience installing and maintaining IT RCS radomes in all sizes across the most challenging environments and conditions, including harsh weather and remote locations. Our crews are equipped with the necessary tools and equipment and are heavy equipment and rope access trained and certified to complete the project quickly and safely.

In addition to installation services, we also offer maintenance and repair services for IT RCS radomes. Our crews have experience maintaining and repairing IT RCS radomes of all sizes in the most challenging environments and conditions. They are heavy-equipment and rope-access trained and certified to complete the project quickly and safely. Our maintenance and repair services ensure your IT RCS radome remains in optimal condition.

Structural engineering is a field that encompasses advanced engineering concepts and demands a high level of application expertise. Our dedicated team at IT RCS is committed to meeting challenging requirements and delivering exceptional results. We employ a comprehensive three-pronged approach to structural analysis, ensuring the reliability and accuracy of our designs.

First, we utilize sophisticated Finite Element Analysis (FEA) techniques to predict the behavior of structures under various conditions. By simulating complex physical phenomena, FEA enables us to assess structural performance, identify potential weaknesses, and optimize designs.

Secondly, we validate the results of FEA through analytical solutions whenever possible. This rigorous process involves obtaining mathematical solutions to verify and cross-reference the predictions made by the FEA models. It allows us to enhance our confidence in the accuracy of our analyses and address any discrepancies.

Thirdly, we conduct mechanical testing to validate both the FEA predictions and analytical solutions. By subjecting physical prototypes or representative samples to controlled experiments, we compare the test results to the analytical models.

This iterative process not only verifies the reliability of our designs but also enhances our understanding of the system’s loading characteristics. Consequently, we continuously improve our future analyses and refine our engineering practices.

At IT RCS, we prioritize safety in every design. Incorporating robust safety factors, we collaborate closely with our clients to determine acceptable risk levels and tailor our products accordingly. By considering the unique requirements and constraints of each project, we ensure that our structural designs meet the highest standards of safety and performance.

Our expertise extends to various structural materials and systems. We specialize in conducting structural analysis for composite structures, such as those made from fiberglass or carbon fiber. Additionally, we have proficiency in analyzing steel, aluminum, and plastic parts, system and connection assemblies, steel structures, and concrete structures.

Moreover, our comprehensive services encompass a wide range of analysis types. These include stress analysis, which assesses the distribution of internal forces and deformations within a structure. We also perform buckling analysis to evaluate the stability of slender structures under compressive loads. Geometry optimization allows us to refine structural designs for enhanced performance and efficiency. Additionally, our capabilities extend to vibration analysis, seismic analysis to assess structures’ response to earthquakes, and foundation analysis to evaluate the stability and load-bearing capacity of foundations.

At IT RCS, we are dedicated to providing reliable and cutting-edge structural analysis services, enabling our clients to make informed decisions and achieve optimal structural performance.

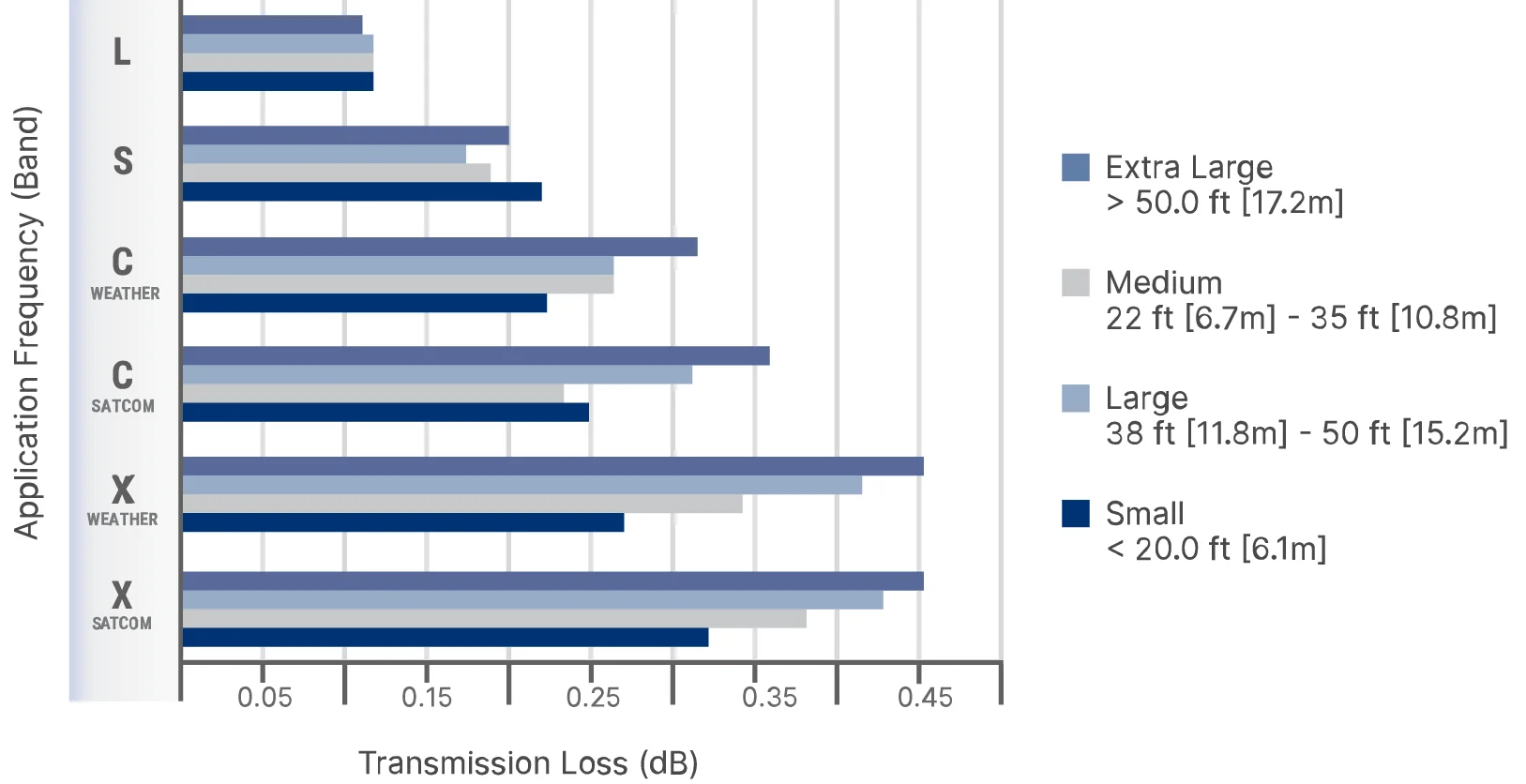

IT RCS approaches each radome order with a thorough review of the customer requirements. After a review of the customer requirements, the level of analysis required for each order is determined. RF Analysis starts with modeling the material properties and the physical dimensions of the proposed materials to estimate the effects of the radome on the system’s performance. Most applications are a trade-off between mechanical properties and electromagnetic effects, requiring some level of optimization. To validate the design, IT RCS uses a number analysis tools including:

The outputs of these RF analyses allows system level requirements for boresight error, sidelobe degradation, total loss due to radome, scattering effects, and other system level requirements to be accurately estimated.

We also have a small 4′ x 8′ 3-axis router used primarily for cutting foam kits for our radome panel.